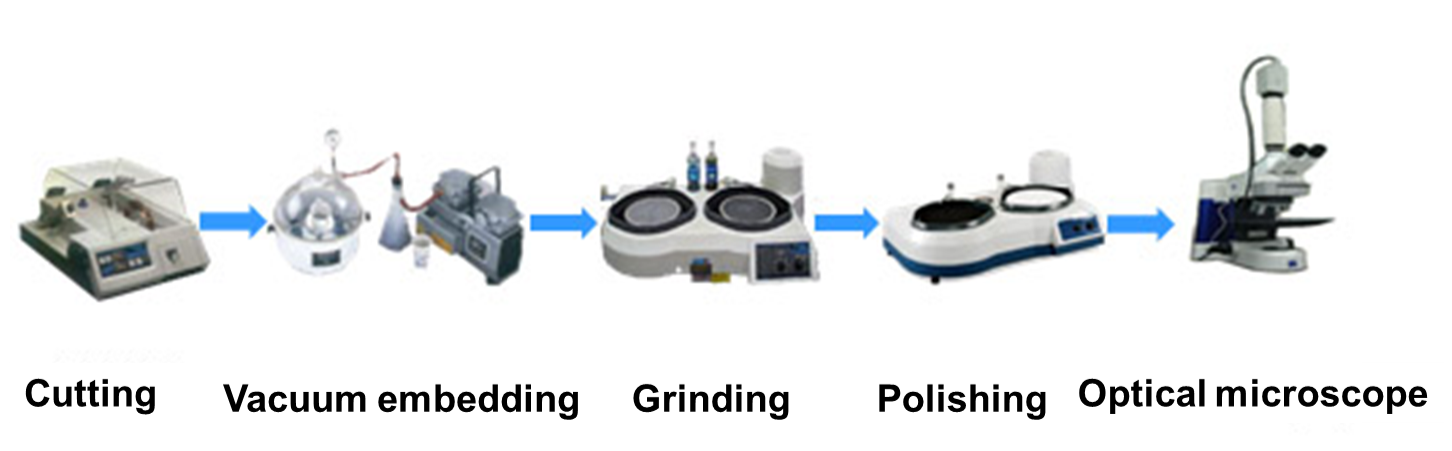

Slicing is a sample preparation method that uses special liquid resin to encapsulate and seal the sample, and then performs grinding and polishing during prototype pcb manufacturing.

The detection process includes sampling, sealing, grinding, polishing, and finally providing a photo of the topography, the judgment of the size of the cracking layer or the size and other data.

Purpose: Inspection of surface and internal defects of electronic components and improvement and verification of circuit board manufacturing.

Scope of application: Suitable for the analysis of electronic component structures, PCBA welding defects, solder morphology and defect detection on solder joints.Equipment used: precision cutting machine, embedding machine, grinding and polishing machine, metallographic microscope, electron microscope, etc.

Test process: sampling, embedding, grinding, polishing, observing and taking pictures.

General inspection items and standards:

1. PCB structural defects: PCB delamination, hole copper fracture, etc..2.PCBA welding quality inspection:

a.BGA soldering, dummy soldering, holes, bridging, tin area, etc.;

b. Product structure analysis: capacitor and PCB copper foil layer analysis, LED structure analysis, electroplating process analysis, material internal structural defects, etc .;

c. Measurement of micro size (generally greater than 1um): air hole size, height of tin, copper foil thickness, etc.

For pcb manufacturing companies, the main purpose:

It is the most commonly used sample preparation method to observe the structure of the sample cross section.1. The sliced samples are usually observed with a stereo microscope or a metallographic microscope;

2. The sliced samples can be used for SEM / EDS scanning electron microscopy and energy spectroscopy to observe the morphology and analyze the components;

3. After performing non-destructive testing such as x-ray and SAM samples, suspected abnormal cracking and foreign body embedding can be observed and verified by slicing;

4. The sliced sample can be used in combination with FIB for more fine microscopic incision observation.

The microsection test is mainly an analysis method used to check the internal conditions and soldering conditions of electronic components, circuit boards or mechanical parts in pcb fabrication and assembly. Abrasive methods are commonly used to expose internal structures or defects in prototype pcb manufacturing.