First, there are many reasons for no copper in the holes of the PCB , which are usually caused by two major processes of dry area and wet area; second, when copper plating is too thin, in the process too many "micro etched" sections lead to copper free holes (rework plate is the most common)

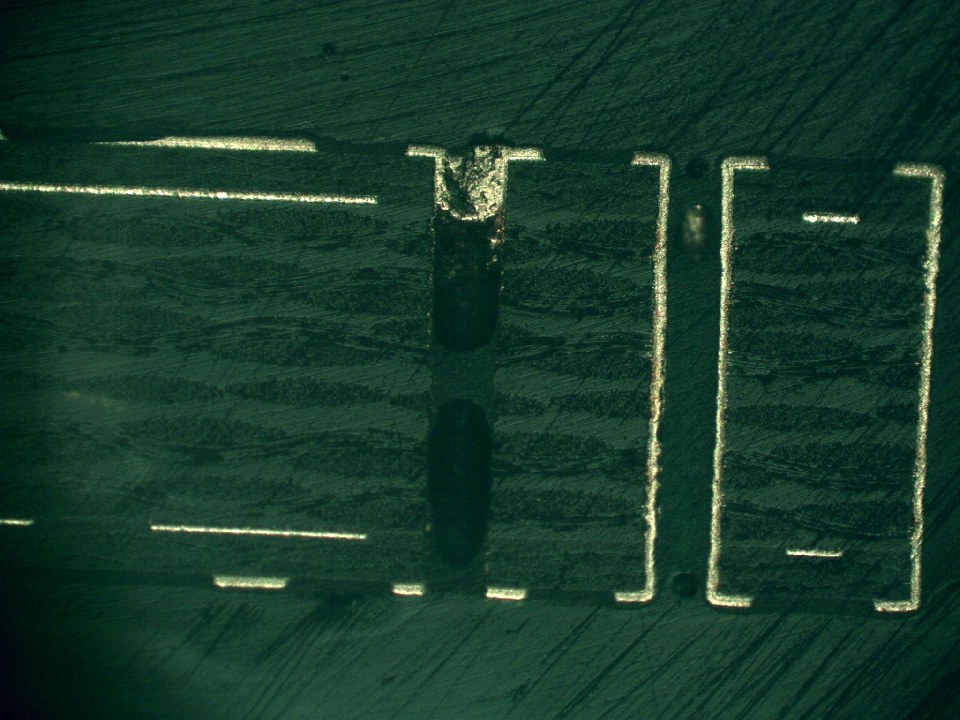

Two. The copper bubble causes holes without copper: the main feature is two copper clad and one copper. The fracture copper is made by Bo Bian hou.

It is mainly caused by the lack of penetration of liquid medicine in the hole and the static state of liquid medicine in the hole, In case of intermittent or continuous breakpoint during plate power supply, two copper clad and one copper are formed after drawing power supply). The poor quality of pore diameter and liquid medicine can also cause this The phenomenon occurs.

No Copper in the Holes of the Printed Circuit Board

Three. Ink hole causes no copper: the two copper at the fracture is not covered by a copper, even a copper bottom copper, no two copper; 1 printing wet.When the film is blocked, the ink can not be fully developed when it is blocked up and developed.

After the process has been bitten by multiple micro etching sections and formed non porous copper, the wet film rework board is most likely to cause ink plugging. 2 or dry film rework Plate, in the caustic soda (NaOH) cylinder for too long time (caustic soda tank there are a lot of dry film broken and impurities, etc.

It has not been replaced for a long time or the dry film is broken without cleaning IV. figure no copper in the hole caused by sundries or bubbles in the hole during electricity: the hole copper fracture is thin and thick, but the distance is short, forming a bubble arc 。

No Cooper inside the Holes

The shape and sundries are different. Two copper does not cover one copper. The main reason is that the copper at the fracture surface is thin and thick, and the distance is short.

Or a copper 2-7um under the sundries will be bitten off by the micro etching process in the production process, and more of the rework plate will be bitten, copper holes The fracture is longer V. no copper in customer complaint hole of finished board: mainly manifested as thin copper plating in process, over etching or rework times in subsequent process production

The number is too much, usually on the client parts, function failure, originally several microns of copper, after the last piece, through the big.

Under the current or strong current, the thin hole copper will be burnt off, resulting in the through hole impassability.