Stariver GroupSubsidiary "Kangtop"have been done the PCB assembly for many years. We focus onPCB assembly,components sourcing, box build . with so many yearsPCB fabricationand assembly manufacturing experience we have gained a lot of experience about BGA soldering.so below are some tips about how to solder BGA components well.Before we start introduction of all the tips pls know the BGA advantages first.

-

Low-inductance leads

-

Heat conduction and easy to do PCB routing

-

High density the balls or pins all underside which can save place and space

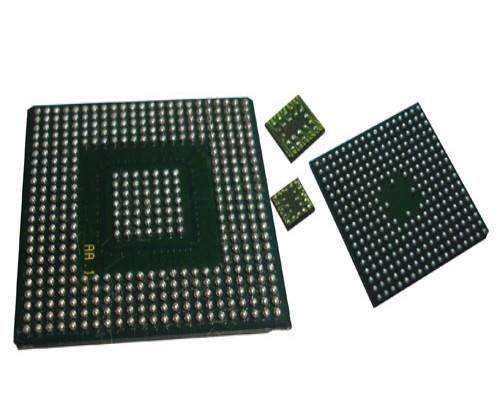

Top and bottom view of a BGA

BGA solder process

Becuase all the pads are below the components and it's not possible checking through visual. So correct procedure become a very important issue when we do the PCB assembly of BGA. But nowadays the technology has been developed so fast and reliable ,so many mass production projects also use this technology.

So firstly is needReflow techniques ,because the whole process of BGA solder need control a tmperature whereby the solder will melt underneath the BGA components themselves.

Secondly must control the solder paste very well,as when heated in the soldering procee, the solder paste will melts Surface tension causes the molten solder to hold the package in the correct alignment with the circuit board, while the solder cools and solidifies.

Thirldy adjust the machine data usually we will use the pick and place file to ensure that BGA components will perfectly put the excatly location where it should be.

BGA solder joint inspection

Usually before assembly the mass production ,we need do an inictial test. Which means we need a necessary inspection after first inspection. But as the solder joints are underneath the BGA components so they can not visible.

So we have to use the X-ray to check the finished assembly.The X-ray can look through the device at the soldered joint beneath.

A key point is when you do the assembly you must control the heat ,sufficient hear must be applied to ensure all the pins in the grid melt sufficiently for every BGA solder joint to be satisfactory made.

BGA rework

There are many PCBA boards which are very comlicated so when you soldered all components if the BGA components didn't assembly perfectly. Then must need do the rework ,and the necessary equipment. If a BGA assembly incorrectly then it is necessary to remove the device. This need use heating the BGA components and melt the solder undeneath.Great care is needed to ensure that only the BGA is heated and removed. Other devices nearby need to be affected as little as possible otherwise they may be damaged.

Stariver Group have rich experience in BGA assembly and if you have more questions or needed BGA assembly projects pls send your details information toinquiry@szstariver.com